Reclaimed Rubber Semi-Products and Products

SNUA recycle Co.

Starting from Plastic , steel , food waste .. ext , In November 2021 SNUA Co. aimed all its effort towards Tire Recycling and opened its tire recycling factory in ARAB Abo Saed industrial area ,Helwan and now trying to extend its industry in 10th of ramadan City as tire recycling products is considered one of the most important needed products now a days in the industrial sector in addition it considered one of the most important waste recycling process that provide high environmental effect as the world right now is going more for green power .

Explore MoreSome Of Our Products!

.

Explore More ProdcutsTire Recycling

The first step in tire recycling is the collection and sorting of used tires. This can be done by waste management companies or tire recycling facilities that purchase scrap tires from tire dealers or individuals.

Once the tires have been collected and sorted, they are shredded into smaller pieces. This can be done using specialized tire shredding machines that cut the tires into small chips or pieces.

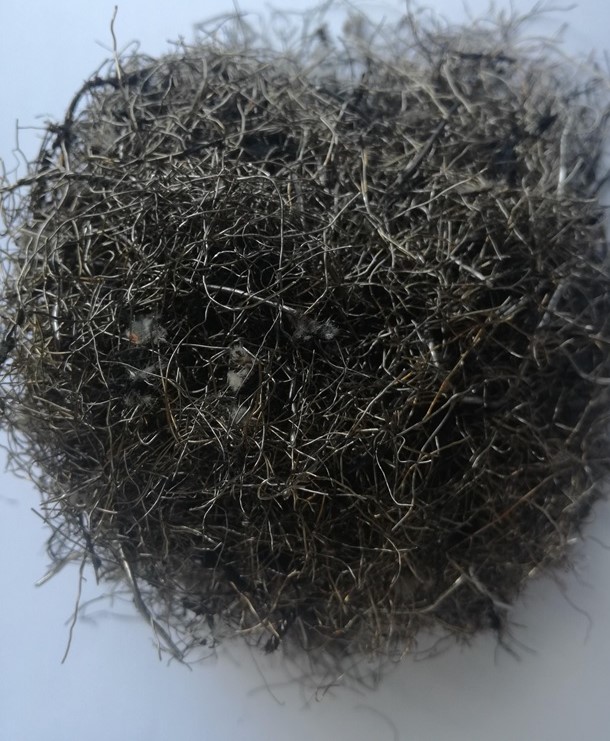

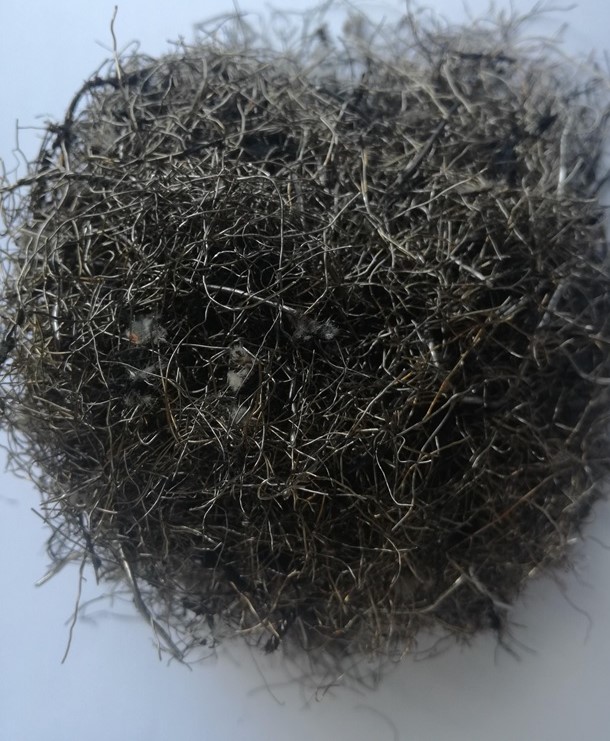

After shredding, the tire chips are typically passed through a magnet that separates the steel wires from the rubber chips. The steel wires are then sent to a steel recycling facility for processing.

The rubber chips that are left after steel removal are then further processed into smaller granules using granulators. This step helps to remove any remaining steel and fiber materials from the rubber.

Some tire recycling processes also involve separating the fiber material from the rubber granules. This can be done using a series of screens and air classifiers that separate the rubber granules from the fiber material.

Once the rubber granules have been separated from steel and fiber, they can be used to create various products, such as playground surfaces, rubber mats, and asphalt. The final processing involves mixing the rubber granules with other materials and heating them under pressure to create a new product.

Our Products

This is produced by shredding and grinding tires into small pieces or granules. It can be used as a raw material in the manufacturing of various products such as athletic tracks, playground surfaces, and rubberized asphalt.

TDF is produced by shredding and grinding tires into small pieces that can be used as a fuel source for cement kilns, pulp and paper mills, and power plants.

This is produced by shredding and grinding tires into small pieces that can be used as a mulch in landscaping and gardening applications.

TDA is produced by shredding and grinding tires into small pieces that can be used as a lightweight fill material in construction applications such as road embankments and retaining walls.

This is produced by heating tires in the absence of oxygen, which breaks down the rubber into a liquid form that can be used as a fuel or chemical feedstock.

Tires contain steel wire that can be extracted and recycled.

This is produced by heating tires in the absence of oxygen, which produces a carbon black material that can be used as a pigment or filler in the manufacturing of rubber products.